By the Assistant Secretary of the Army for Acquisition, Logistics and Technology Public Affairs Office

WASHINGTON – United Aircraft Technologies, Inc., a small business run by a former U.S. Army aircraft electrician and his wife, made their first pitch to the Army in 2018, when they submitted a proposal to the xTechSearch 2 Competition, which sought technology solutions that can fill critical mission gaps for Soldiers.

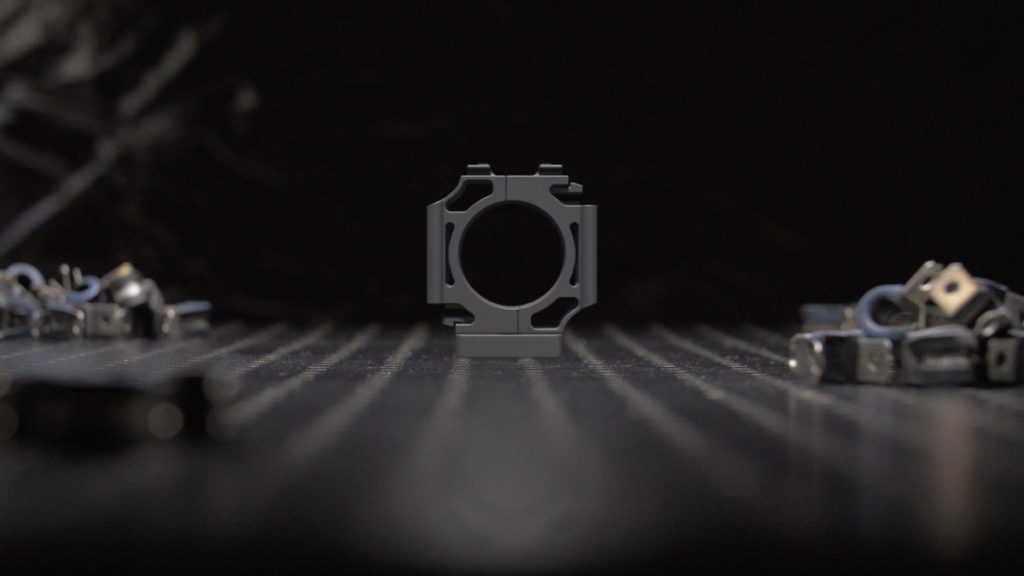

They were ultimately named a finalist in the competition, and UAT’s run with the Army and the evolution of their technology, the Interconnecting Clamp, is far from over; the company hopes to one day leave a major footprint on the future of aircraft wire management.

TECHNOLOGY WITH A HUMAN ELEMENT

Daryian Rhysing, UAT chief technology officer, and his wife, Evaguel Rhysing, UAT chief executive officer, took Daryian’s experience as an Army veteran into consideration during the development of their signature innovation. As opposed to traditional metal legacy clamps, UAT’s ICC has a lightweight, thermoplastic and ergonomic design. Each clamp has a network of embedded sensors that can map, monitor and diagnose the entire electrical system on any vehicle in just a few hours, which usually takes two or more weeks to complete.

The ICC also simplifies installation, reduces physical injuries, lowers costs and time, lightens the aircraft and increases aircraft readiness. Daryian noted that their innovation also enhances safety because a lighter aircraft can have the ability to carry an extra Soldier out of a combat zone.

EXPERIENCE INSPIRES INNOVATION

Several years prior to xTech and the birth of the ICC, Daryian injured his hand while serving in the Army as an aircraft electrician. For 14 years, he spent countless hours fixing aircraft wiring systems that used traditional metal clamps. This repetitive work put constant strain on his hand muscles; Daryian developed carpal tunnel syndrome, resulting in weakness of his hands and, ultimately, the inability to continue working as an electrician.

Daryian had to determine a new path forward to support his family, so he went back to school and earned an engineering degree from Rensselaer Polytechnic Institute in 2016. Daryian decided to use his engineering knowledge and his experience as an aircraft electrician to solve the problem that had affected him personally – a repetitive strain injury in his hands.

“I felt like I was actually helping Soldiers in the same industry as me, because the majority of the employees that I worked with suffered in silence,” said Daryian.

HOME IS WHERE THE ARMY IS

After their innovation was developed, Daryian and Evaguel took their solution back home – to the Army – by submitting a proposal to xTechSearch 2. The xTech Program gives cutting-edge technologies the chance to be integrated into the Army’s ecosystem, compete to earn significant cash prizes and the potential to acquire follow-on contracts and awards with the Army.

UAT pitched their innovation to xTech and made it to the third phase of the xTechSearch competition, where they were named one of the top 12 finalists at the Association of the United States Army Global Force Meeting in March 2019.

While they weren’t named the winner of the competition, the opportunities stemming from xTech are helping UAT leave a major footprint on the future of aircraft wire management. The Rhysing’s small business is now in the aviation game with some of the industry’s biggest players. They are hoping to implement their clamps into the military’s next generation of helicopters, and are even broadening their reach into the Navy and commercial aerospace market.

“A lot of the connections we were able to make are thanks to xTech,” said Evaguel, noting that major manufacturers within the Department of Defense are now partnering with UAT because of the xTech process that helped them to validate their product.

In 2019, following the competition, UAT received a Phase I contract from the Army Applied Small Business Innovation Research Program, a congressionally-mandated program that helps small businesses meet the Army’s continual research and development needs. After successfully proving their prototype during Phase I, the Applied SBIR Program recently awarded UAT a Phase II contract to further develop their ICC for the future of vertical lift, which aims to modernize and field new helicopters for the Department of Defense.

SMALL BEGINNINGS TO BIG REALITIES

Coming from small beginnings with just two employees, Daryian and Evaguel, UAT has transformed its business from a far-away goal to a reality that is modernizing the aviation industry. Now with over 15 employees, business is booming and their technology is evolving, with their clamps currently being put into helicopters to be flown for longer periods of time. While the Rhysings’ hard work and ingenuity is the driving force behind their success, they also give credit to their participation in xTech because the program was one of the first to really believe in their technology.

“I encourage other companies, no matter what stage you are in the process, to take the opportunity with xTech,” said Evaguel. “They look not at the size, not at how much money you have, but at the potential opportunity and the capability of the team to execute.”

For more information on UAT and its transformative ICC technology, visit their website at https://uairtek.com. You can also visit the xTech website at www.xtech.army.mil to learn more about the Army’s approach to modernization and how you can get involved.